24/7 Emergency Service

+86 185 2662 3967

Contact Us Now!

24/7 Emergency Service

+86 185 2662 3967

Contact Us Now!

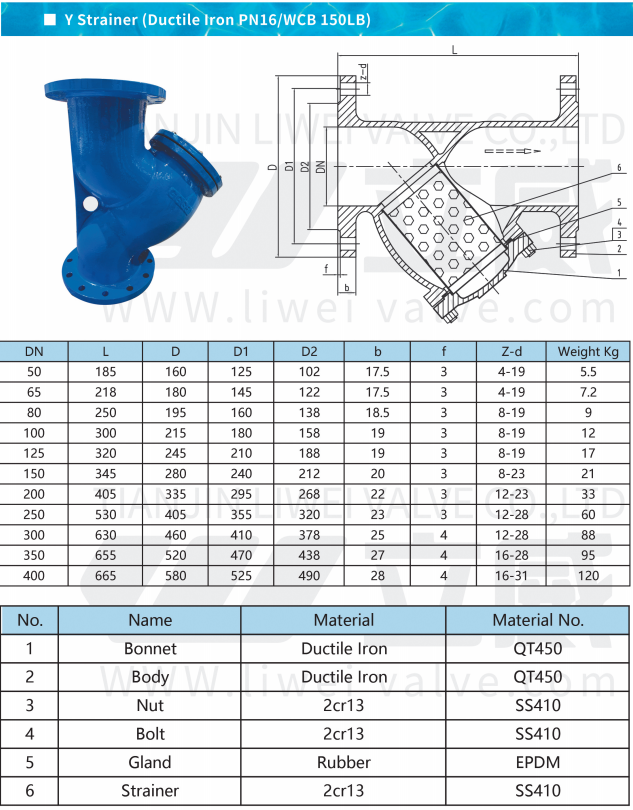

Body: Cast Iron/Ductile Iron/Stainless Steel GG25/GGG50 CF8

Cover: Cast Iron/Ductile Iron/Stainless Steel GG25/GGG50 CF8

Screen/bolt/nut: Stainless steel SS304/SS410

Paiting: Blue epoxy power coating or customized

Standard:PN10/16 150LB

Parameter

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment.

Y-Strainers are very cost effective straining solutions in many applications. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap. For applications with heavier dirt loading, Y-Strainers can be fitted with a "blow-off" connection that permits the screen to be cleaned without removing it from the strainer body.

Y-Strainers are used in a wide variety of liquid straining applications to protect downstream process system components in many industries, including: chemical processing, petroleum, power generation and marine. Water handling applications, where Y-Strainers are used to protect equipment that could be damaged or clogged by unwanted sand, gravel or other debris, are very common.

Advantage

Describe

Bolted cover with blow-off drain plug

Packing Details:

Normal We use 1.1*1.1*1.1m Wooden Box

Each Valve we use 1 pcs bubble bags and 1 pcs plastic bags

1 20GP container can loading 20 * 1.1*1.1*1.1m wooden boxes

1 20GP container can loading 24-26Ton

1 1.1*1.1*1.1m wooden box can loading valves qty

Calculate Base On Y-Strainer PN16

1 1.1*1.1*1.1m wooden box can packing 2inch 65Pcs

1 1.1*1.1*1.1m wooden box can packing 2.5inch 55Pcs

1 1.1*1.1*1.1m wooden box can packing 3inch 50Pcs

1 1.1*1.1*1.1m wooden box can packing 4inch 40Pcs

1 1.1*1.1*1.1m wooden box can packing 5inch 35Pcs

1 1.1*1.1*1.1m wooden box can packing 6inch 30Pcs

Each Wooden Box weight is 60-65KG

Tags

Latest News

Factory Add.:

No.3 Xintai Road, Jinnan District, Tianjin, China.

Office Add.:

C12 Aliyun Jinnan District, Tianjin, China.

Name: Riven Lee

Mob.: +86 185 2662 3967

E-mail: trading_manager@liweivalve.cn

Name: Ariel Wong

Mob.: +86 186 9809 4027

Name: Kerry Zhang

Mob.: +86 187 2267 7875

Navigation

Products

Leave a Message